Linear roller, telescopic and cylindr guides

With two types of C-profile, LR and LUR, and a steel roller slider, the system is highly rigid and

suitable for the most demanding applications in terms of load capacity, dynamics and

environmental conditions.

The guide profiles are made of zinc galvanized cold-drawn carbon steel. Raceways can be heat

treated and subsequently ground. The LR and LUR profiles combination can compensate axial

misalignment up to 3.9 mm.

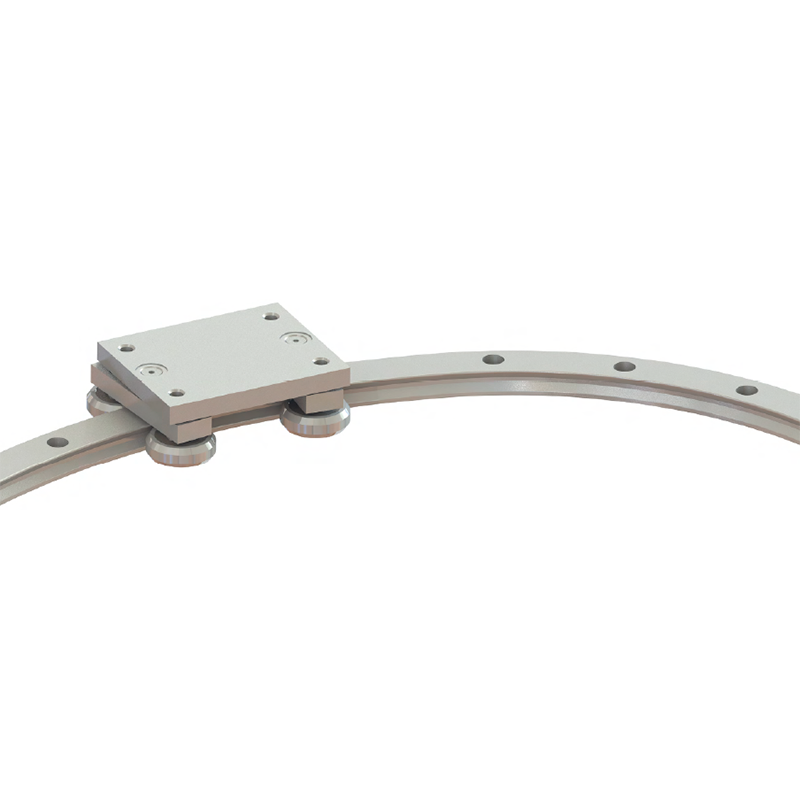

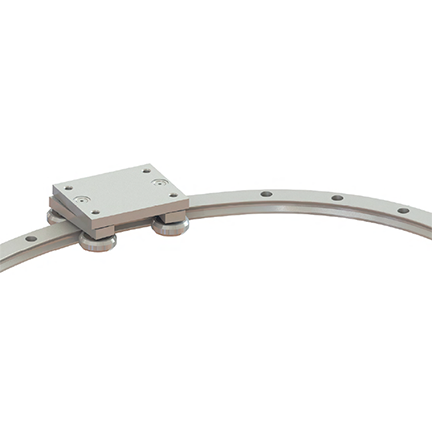

Guides of this series are designed to move the load along a curvilinear path. Guides are customized to meet specific requirements, allowing unique solutions to be created.

Three roller sliders in zinc plated formed steel profile. This series is designed for applications that require good performance at an affordable price. There are 3 type-sizes in the series, depending on the height of the profile: 20, 30, 45.

Telescopic guides with full and partial extension are made of cold-drawn steel profile. The variety of shapes of the middle element makes it possible to find the appropriate solution for all applications.

Lightweight telescopic guides with full extension LIGHTSLIDE are made of galvanized sheet steel. Guides are available in four sizes depending on profile height: 45, 53, 71 and 76. Sizes 53 and 76 are available with locking mechanism in open and closed positions. All guides are equipped with a locking device in closed position. Guides construction allows to remove movable slider for separate mounting (except size 76).

| Code | Load capacity of a pair of guides | Max leigth | Max stroke | Operated temp. °C |

| TLSB45-250-255 | 500 H | 600 mm | 610 mm | from -10 to +40 °C |

| TLSB45-300-305 | ||||

| TLSB45-350-355 | ||||

| TLSB45-400-405 | ||||

| TLSB45-450-455 | ||||

| TLSB45-500-505 | ||||

| TLSB45-550-555 | ||||

| TLSB45-600-605 |

| Code | Load capacity of a pair of guides | Max leigth | Max stroke | Operated temp. °C |

| TLSB53-400-415 | 1100 H | 1000 mm | 1000 mm | from -10 to +40 °C |

| TLSB53-500-515 | ||||

| TLSB53-600-615 | ||||

| TLSB53-700-715 | ||||

| TLSB53-800-815 | ||||

| TLSB53-900-915 | ||||

| TLSB53-1000-1015 | ||||

| TLSB53Z-400-397 | ||||

| TLSB53Z-500-497 | ||||

| TLSB53Z-600-597 | ||||

| TLSB53Z-700-697 | ||||

| TLSB53Z-800-797 | ||||

| TLSB53Z-900-897 | ||||

| TLSB53Z-1000-997 |

| Code | Load capacity of a pair of guides | Max leigth | Max stroke | Operated temp. °C |

| TLSB71-500-500 | 1100 H | 1000 mm | 1000 mm | from -10 to +40 °C |

| TLSB71-600-600 | ||||

| TLSB71-700-700 | ||||

| TLSB71-800-800 | ||||

| TLSB71-900-900 | ||||

| TLSB71-1000-1000 |

| Code | Load capacity of a pair of guides | Max leigth | Max stroke | Operated temp. °C |

| TLSB76-450-450 | 2720 H | 1200 mm | 1200 mm | from -10 to +40 °C |

| TLSB76-500-500 | ||||

| TLSB76-600-600 | ||||

| TLSB76-700-700 | ||||

| TLSB76-800-800 | ||||

| TLSB76-900-900 | ||||

| TLSB76-1000-1000 | ||||

| TLSB76-1100-1100 | ||||

| TLSB76-1200-1200 | ||||

| TLSB76Z-450-450 | ||||

| TLSB76Z-500-500 | ||||

| TLSB76Z-600-600 | ||||

| TLSB76Z-700-700 | ||||

| TLSB76Z-800-800 | ||||

| TLSB76Z-900-900 | ||||

| TLSB76Z-1000-1000 | ||||

| TLSB76Z-1100-1100 | ||||

| TLSB76Z-1200-1200 |

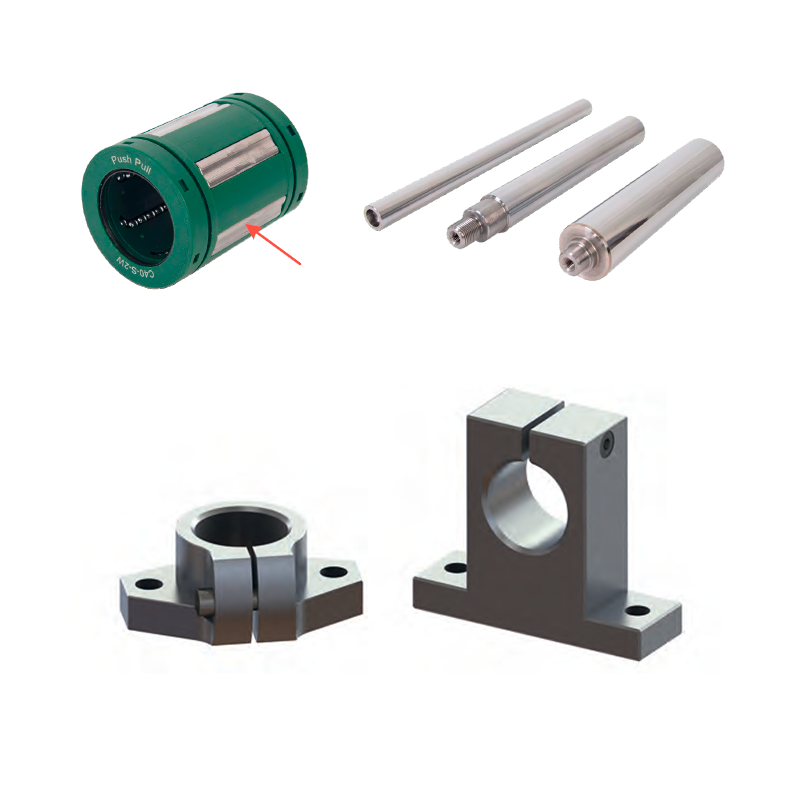

Cold-drawn steel C-profile. System includes a linear guide with a C-profile with one or more sliders moving in a ball cage. This series has the highest load capacity of PUSH PULL products.

Bushing design allows to compensate angular deviation up to 0.5° between shaft and bushing axes. Position repeatability and accuracy of the raceways of metal inserts and balls allows to achieve a higher load capacity in the same standard size compared to other bushings.

| Code | Load capacity, kg/m | Tolerance, h6 μm | Hardering depth | fx45°, mm |

| LC12-1-h6 | 0.89 | -11 | ≥0.8 | 0.5 |

| LC12-1000-h6 | ||||

| LC12-2000-h6 | ||||

| LC12-3000-h6 |

| Code | Load capacity, kg/m | Tolerance, h6 μm | Hardering depth | fx45°, mm |

| LC16-1-h6 | 1.58 | -11 | ≥1.5 | 0.5 |

| LC16-1000-h6 | ||||

| LC16-2000-h6 | ||||

| LC16-3000-h6 | ||||

| LC16-4000-h6 |

| Code | Load capacity, kg/m | Tolerance, h6 μm | Hardering depth | fx45°, mm |

| LC20-1-h6 | 2.47 | -13 | ≥1.5 | 1 |

| LC20-1000-h6 | ||||

| LC20-2000-h6 | ||||

| LC20-3000-h6 | ||||

| LC20-4000-h6 |

| Code | Load capacity, kg/m | Tolerance, h6 μm | Hardering depth | fx45°, mm |

| LC30-1-h6 | 5.55 | -13 | ≥2 | 1 |

| LC30-1000-h6 | ||||

| LC30-2000-h6 | ||||

| LC30-3000-h6 | ||||

| LC30-4000-h6 |

| Code | Load capacity, kg/m | Tolerance, h6 μm | Hardering depth | fx45°, mm |

| LC40-1-h6 | 9.87 | -16 | ≥2.5 | 1 |

| LC40-1000-h6 | ||||

| LC40-2000-h6 | ||||

| LC40-3000-h6 | ||||

| LC40-4000-h6 |

| Code | Load capacity, kg/m | Tolerance, h6 μm | Hardering depth | fx45°, mm |

| LC50-1-h6 | 15.4 | -16 | ≥2.5 | 1 |

| LC50-1000-h6 | ||||

| LC50-2000-h6 | ||||

| LC50-3000-h6 | ||||

| LC50-4000-h6 |

| Code | Diameter of shaft ⌀ d, mm | Row of balls | Cmin, H | Cmax, H | C0min, H | C0max, H |

| C12-S-2W | 12 | 5 | 1020 | 1397 | 1290 | 1870 |

| Code | Diameter of shaft ⌀ d, mm | Row of balls | Cmin, H | Cmax, H | C0min, H | C0max, H |

| C16-S-2W | 16 | 5 | 1250 | 1712 | 1550 | 2278 |

| Code | Diameter of shaft ⌀ d, mm | Row of balls | Cmin, H | Cmax, H | C0min, H | C0max, H |

| C20-S-2W | 20 | 6 | 2090 | 2549 | 2630 | 3340 |

| Code | Diameter of shaft ⌀ d, mm | Row of balls | Cmin, H | Cmax, H | C0min, H | C0max, H |

| C30-S-2W | 30 | 6 | 5470 | 6673 | 6810 | 8716 |

| Code | Diameter of shaft ⌀ d, mm | Row of balls | Cmin, H | Cmax, H | C0min, H | C0max, H |

| C40-S-2W | 40 | 6 | 6590 | 8039 | 8230 | 10534 |

| Code | Diameter of shaft ⌀ d, mm | Row of balls | Cmin, H | Cmax, H | C0min, H | C0max, H |

| C50-S-2W | 50 | 6 | 10800 | 13176 | 13500 | 17280 |

| Code | Diameter, mm | Weight, g |

| SS12 | 12 | 30 |

| SSF12 | 12 | 20 |

| Code | Diameter, mm | Weight, g |

| SS16 | 16 | 40 |

| SSF16 | 16 | 27 |

| Code | Diameter, mm | Weight, g |

| SS20 | 20 | 70 |

| SSF20 | 20 | 40 |

| Code | Diameter, mm | Weight, g |

| SS30 | 30 | 180 |

| SSF30 | 30 | 110 |

| Code | Diameter, mm | Weight, g |

| SS40 | 40 | 420 |

| SSF40 | 40 | 510 |

| Code | Diameter, mm | Weight, g |

| SS50 | 50 | 750 |

| SSF50 | 50 | 890 |